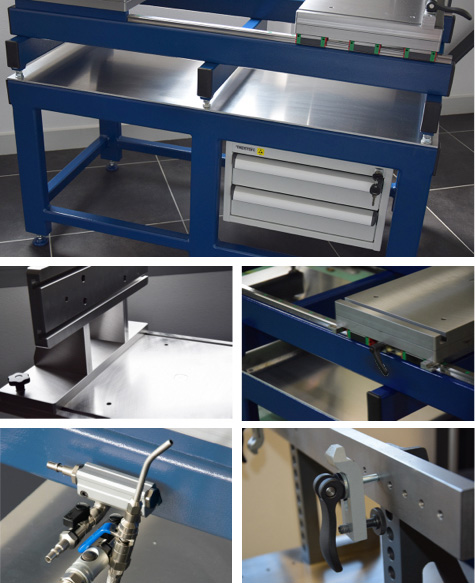

Split Table Injection Mold Table

Modern Maintenance Starts Here

Built for Injection Molders Who Can’t Afford to Waste Time

Injection molding operations demand uptime. Our mold tables are designed to keep your production floor moving:

- Split Access for effortless mold opening and inspection

- Load Capacities up to 6000 kg (13,228 lbs)

- Customizable Sizes for your specific platen and mold requirements

- T-Slot Compatibility for seamless integration

- Height Blocks Available upon request

Static benches aren’t built for today’s demands.

When it comes to mold maintenance, every delay costs you. Split Table Injection Molding Mold Tables are engineered to eliminate inefficiencies, reduce safety risks, and give your team the ergonomic workspace they need to perform precision work—fast.

Easy Opening, Closing and Rotating Access to Molds for Maintenance & Repair

Transform Your Maintenance Process Today

Start Saving Time & Money Now

Choose the Right Capacity for Your Operation

2000 kg / 4409 lbs

3000 kg / 6613 lbs

6000 kg / 13228 lbs

The Smarter Way to Service Molds

Outdated static benches create bottlenecks, strain your team, and lead to rushed or incomplete repairs. A Split Table Injection Molding Mold Table puts everything in place—literally—for fast, safe, and consistent maintenance.

Reduce Downtime. Cut Costs. Protect Your Team.

Let your maintenance area become a competitive advantage.

Why Smart Manufacturers are Making the Switch

- Cut repair time by up to 40%

- Reduce injury risk for technicians

- Eliminate avoidable mold damage during handling

- Improve technician satisfaction and retention

Let’s Talk

Want to see how a Split Table can fit into your facility? Get expert advice and a custom quote today.